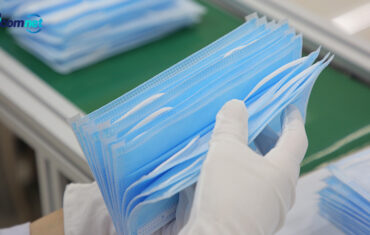

All face mask wholesale manufacturers design masks to protect users against the transmission of bacteria. They also prevent the spread viruses such as coronavirus. Face mask wholesale manufacturers worldwide are transforming production lines to meet the growing needs of people. As a buyer or seller, how confident are you in your process and product controls in meeting regulatory as well as brand specifications in these most challenging times.

Quality requirements

During coronavirus, all exports of face masks should meet the qualification standards of either US or the importing nation. When declaring such an export, face mask wholesale manufacturers must submit an electronic or written announcement. They are jointly signed by the exporter and the foreign importer, attesting that the product meets this requirement. In addition, the foreign importer must attest that they accept the qualification standard.

The quality requirements of face mask generally include two categories. They are the use requirements of the mask and the performance requirements of the mask. The mask need to cover the wearer’s mouth and nose. It should have good facial tightness. Besides, manufacturers make sure that the surface of face mask not damage or stain. The mask should also meet certain grade of rubbing color fastness. And the mask belt meet certain breaking strength and so on. The performance requirements of masks base on the relevant standards. The EU and the US standards have different performance requirements for masks. Face mask wholesale manufacturers should do the corresponding test according to the standards. Such as air permeability test, flame test, and wet resistance test and so on.

ISO standards

There are different types of face masks that help prevent the spread of disease: from a typical surgical mask to an N95 respirator. This equipment is crucial to help keep workers safe. However, these masks only protect users if they are defect free and pass stringent ISO standards. This is challenging for face mask wholesale manufacturers when demand far exceeds existing supply.

Manufacturers should check the quality of face masks to prevent defective products from making it to the market. They are including checking for flaws such as embedded hair or stains, measuring the width of the mask. They are also checking for the presence of straps, and determining that it is correctly attached to the mask. Face mask wholesale manufacturers need to ensure their masks in compliance with ISO standards. They also catch defective masks before they are shipped. They also measure the width of the masks to ensures they are manufactured to the correct size.

Summary

Face mask wholesale manufacturers are racing to fulfill overseas demand for this products. Therefore, industry observers said global cooperation need to ensure the quality. Pressured by the need to address the epidemic, many countries have relaxed entry standards for face masks. So many non-professional players are taking the chance, which may hurt regular market practices. Therefore, face mask wholesale manufacturers should make sure no substandard products are shipped. Then, importers need to do their job to step up supervision, tracking and inspection.