More Vietnam companies are trying to get into the mask-making business. Because they realize that hospitals and public officials scrounge for protective gear confronting the coronavirus pandemic. In the fight against the coronavirus, medical mask worn by millions of people around the globe everyday. Then, Vietnam government is under growing pressure to share and meet the world’s needs. Hundreds of millions of masks have been exported abroad because of the development of medical mask factories in Vietnam.

High quality of medical masks

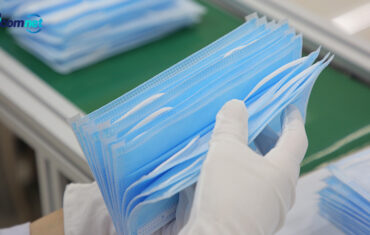

Excellent quality medical masks can reduce exposure to blood and other bodily fluids with a 99% filtration fluid resistance. In today’s medicine, a medical mask is a necessary respiratory and contact precaution. This shows an upsurge in the operation and production capacity of medical mask factories in Vietnam. However, there are still many things to do to facilitate the sustainable export of medical masks.

Professional manufacturers

After recognizing the increasing demand for masks, Vietnam companies transform the challenges into opportunities by switching to produce medical masks. They decided to convert clean rooms designed for producing liquid crystal display panels into lines for making masks. The domestic firms no longer rely on imported materials such as antibacterial fabrics or chemical substances. Instead, they could produce antibacterial fabrics made from domestically biological materials. They also are operating under their capacity due to the lack of customers and orders. So far, many medical mask factories in Vietnam said that they got long-term contracts on face masks production.

Strong position in export markets

Medical mask factories in Vietnam and textile businesses have achieved a strong position in export markets. As of April 19, Vietnam exported over 415 million face masks. However, they may face difficulties in meeting mask quality standards from the importing countries. In the U.S, officials project the country has just one percent of the 3.5 billion medical masks and respirators needed to fight the outbreak for a year. To export masks to the EU and the US, Vietnamese firms must obtain a CE marking and FDA certification. Therefore, they indicate that a product meets the appropriate safety and environmental protection standards.

Medical mask factories in Vietnam had set its own hygiene and environment friendly standards. All employees are trained regularly for personal hygiene and clean room environment. They ensure comprehensive and exhaustive series of physical, chemical and biological testing at different stages in the production cycle. Quality process starts right from the procurement of raw material ensuring that it fulfills the requirement of internal use and international biological standards. In a large demand for face masks, the EU and US may allow the import of these products without CE marking and FDA certification.

Overall

Medical mask factories in Vietnam should well-prepare right from the start of the production process in order to raise their competitiveness. They also need to promote their exports medical masks in the long term. Particularly focus on demanding markets like the US and EU. The bigger ability of production will be the opportunities for medical mask factories in Vietnam to step into the world market. However, medical mask factories in Vietnam will face competitiveness issues when other countries with success in developing that products, including China and India.