The garment industry was suffering an unprecedented crisis due to COVID-19. However, the pandemic also brought significant opportunities for Vietnam to become the world’s face mask supplier. Many face mask suppliers recently invested in producing face masks as a solution to cope with the difficult time. Then, they can take the opportunities arising from the supply shortage.

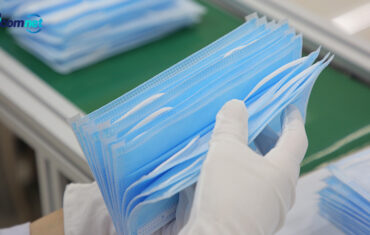

Some face mask suppliers received export orders worth millions of dollars. This is a positive sign for the garment industry which was under huge pressure from the pandemic. Demand is high while masks are a product that does not require much investment. Basically, every textile workshop with existing equipment and workers can produce masks. Therefore, the ability to produce masks of face mask supplier is very large. After meeting all domestic needs, it is completely possible to export.

High quality of mask

Materials for producing masks are not too complicated. Previously, businesses had to import antibacterial fabric or chemicals to produce antibacterial fabric. However, currently, some businesses have able to produce antibacterial fabric entirely from domestic bio-materials. Therefore, if there is high demand, they could further improve the current mask production capacity.

Development of cloth mask

In addition to medical masks, face mask suppliers can also export cloth masks. Since the demand for cloth masks increased, businesses have invested in the design and materials to improve this product. Many businesses have even produced 3-layer and 4-layer masks. In addition to the antibacterial layer, there are an additional layer of water-proof and anti-splash cloth.

Long-term investment

However, face mask suppliers in Vietnam need to give careful consideration when investing in face mask production as a long-term or large-scale investment. This is because demand for masks could drop when the pandemic was over. Therefore, face mask suppliers must pay attention to meeting quality and safety requirements of the import markets. They also need to obtain certificates to expand exports. To export face masks and PPE to the EU, face mask suppliers must get CE marking. CE indicated that a product had been assessed by the manufacturers and deemed to meet EU safety, health and environmental protection requirements. The mass of face masks and PPE without following technical standards would cause oversupply if manufacturers could not exported to other countries.

Sumarry

Now, Vietnam is fully capable to become the world’s face mask factory. However, face mask suppliers need to be further careful consideration when investing in this product as a long-term. Or large-scale investment is still needed. Firstly, face masks are becoming an essential item during the COVID-19 outbreak. But demand for the product could drop when the pandemic was over. Thus, it is a seasonal product with low stability. Secondly, face mask producers must pay attention to meeting quality and safety requirements of the import markets.